In other words, the challenges in modern industries are that they require effective, safe, efficient and flexible material processing. From foundries to bulk handling plants, from quarries to ore plants and from steelworks to daily use kitchens, our rotary machines is the right solution to any industrial process. These machines provide continuous, reliable movement to handle and cool or dry or separate material and are known in the industry to be essential, particularly with regard to producing a consistent high-volume output.

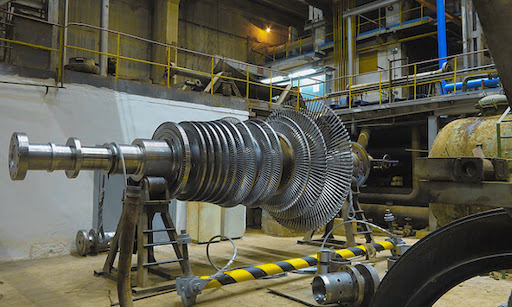

What Is Rotary Equipment?

Rotary equipment is the type of equipment which are performed with their work in rotary or rotating directions such as colors mixing, stirring and grinding. As stuff tumbles in, it undergoes various processes–cooling from having been cast, drying after soaking up some moisture, breaking down because it’s easier to use that way, etc.

The following are some of the industries that utilize rotary machines:

- Foundries – for casting coolers, sand return and shakeout

- Recyclers – to screen and sort material

- Mining and Agriculture – for bulk material drying and handling

- Chemical and Cement plants – for crushing raw materials such as limestone and shale.

Core Benefits of Rotary Equipment

Rotary valves excel when they can run all kinds of material. This is the reason they are prized in such arduous environments:

- Tumbling: Tumbles media, parts, & unfinished assemblies for exposure to air, heat or other vectors.

- Adjustable: Works with fine thin powders all the way to heavy abrasive materials

- Rugged carry: Reinforced walls and high-impact spring feet to endure up to 1000 pounds of pressure without deforming, even in the extreme heat of battle

- Mow with less effort: Customized adjustments for a return on investment run after run

These characteristics help to make sure that the operation could run smoothly even when in constant use.

Industrial Applications in Action

Castings are cleaned and sand is reclaimed in a foundry by a rotary drum; the labor being greatly reduced and the quality improved. Trommels and dryers help recycle scrap and waste in recycling plants. And in bulk material industries, conveyors transport sacked or loose material so delicately that it does not break down or become distorted.

Some popular uses include:

- Fast cooling of hot castings and sand

- Drying minerals before shipping

- To recover metals from dross that is left over from completed or interrupted production

- Recovering regenerative sand from solidified lumps

Designed for Efficiency and Safety

One of the big benefits of these types of machines is that they can decrease manual handling and the potential for exposure to risks. Whether it’s high heat or aggressive materials, use of rotary systems for automation gets the job done faster and safer. Maintenance is simplified as well, quickly replaceable liners and modular components reducing downtime.

How General Kinematics Elevates Performance

If the decades of material processing experience offered by GK’s rotary equipment isn’t enough of a testament to the quality, durability, and reliability of these rotary products, then take a look at our company’s illustrious clientele who’ve been eagerly using our rotary machines for heavy duty applications. Their solutions enable increased throughput, reduced waste and unparalleled reliability – even in the most taxing of conditions. From cooling drums to sand reclaimers, their portfolio is designed for efficient operation and simple use.

For more information on their full equipment solutions, visit General Kinematics’ rotary equipment page.

Final Thoughts

Whether you’re operating a foundry or a recycling facility, the quality of your processing can mean the difference between a bad day and a good day. With the proper configuration, you get more uptime, better output and a safer working environment. With reliable equipment like General Kinematics, you can ensure that you’re backed by the very best performance — and innovation that serves as hard as you do.